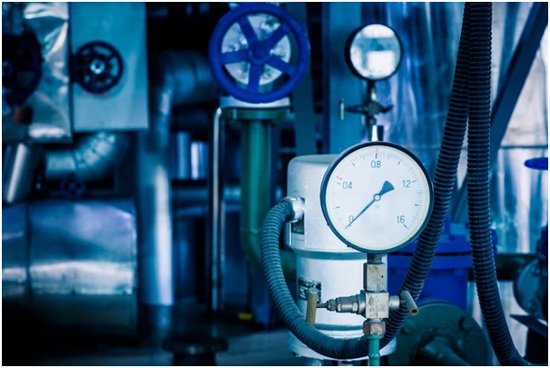

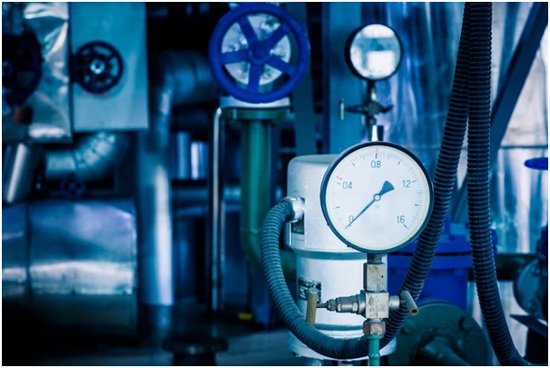

A flow meter is a tool that calculates the volume of liquid, gas, or vapor flowing through a conduit or pipe.

Applications of Flow Meter

Chemical applications

- Acid measurement

- Gas Distribution

- Waste gas and flare monitoring

- Gas supply

Food and Beverage industry

- Breweries

- Measuring Starch Concentration

Power and Utility

- Biogas from landfills in cogeneration power plants

- Steam production using waste methane gas from manure digesters

- Boiler Control System

Marine

- Reverse osmosis

- Marine Loading

- General flow meter requirements onboard ships

Metal and Mining

- Steel Mills

- Fuel flow monitoring

Oil and Gas Industry

- Crude Oil and Gas Production

- Satellite and pump station

- Leak Detection in Pipeline

Pharmaceuticals

- Hygienic flow measurements

- Pill Coating

- Monitoring hydrogen bleed-off

Pulp and Paper

Water and wastewater

- Water Distribution Networks

- Drinking water

- Aeration

Types of Flow Meter

1. Differential Pressure Flow Meter

The most widely used device today for measuring fluid flow is a differential pressure flow meter, which works by reading the pressure loss across a pipe restriction. They consist of two parts: a primary element that alters kinetic energy and causes a difference in pressure inside the pipe, and a secondary element that provides the signal or read-out that is converted into the actual flow value.

This kind of device is used in more than half of applications for measuring liquid flow. It is the most popular among the flow meter manufacturers in India.

2. Orifice Flow Meters

Orifice flow meters are currently the most widely used liquid flow meters. An orifice is a flat piece of metal with a hole of a specific size bored into it, to put it simply. Although segmental, eccentric, and conical (quadrant) designs are also available, concentrated orifices are predominately in use.

The orifice plate is mounted in the pipe between two flanges. The main component, an orifice, limits liquid flow to exert a differential pressure across a plate. Orifices are a great option for pipes of all sizes due to their lack of moving parts and relatively low cost.

3. Venturi Flow Meters

In order to handle large flows at low-pressure drops, venturi tubes are segments of pipe with a tapered entrance and a straight throat. They can be fitted with flanged, welded, or threaded end fittings to be installed in large-diameter pipes, and they have four or more pressure taps to average the pressure. The majority of liquids, including those with a high solids content, can be used with them.

4. Pitot Tube Flow Meter

Installing pitot tubes typically involves welding a coupling to a pipe and passing the probe through the coupling. Most pitot tubes can only be used for single-point measurements. The units could become clogged if there are foreign particles in the liquid. Pitot tubes have several benefits, including affordability, the lack of moving parts, simplicity of installation, and minimal pressure drop.

5. Positive Displacement Flow Meters

These machines work by dividing liquids into precisely measured increments and moving them on. A connecting register counts each segment. Positive-displacement units are widely used in automatic batching and accounting applications because each increment represents a discrete volume.

Positive-displacement meters are suitable for use where a straightforward mechanical meter system is required or for measuring the flows of viscous liquids.

6. Volumetric Flow Meters

With regard to the volume flow rate, these instruments operate linearly. They are more flexible because there is no square-root relationship. Most housings for velocity-type meters have flanges or fittings that enable direct attachment to pipelines.

7. Turbine Flow Meters

For precise liquid measurement applications, turbine meters are commonly used. The device consists of a pipe mounted with a multi-bladed rotor that is perpendicular to the liquid flow. The liquid flows through the blades as the rotor rotates.

Magnetic pick-up, photoelectric cells, or gears can all be used to measure rotational speed, which is a direct function of flow rate. It is possible to count and add up electrical pulses.

8. Ultrasonic Flow Meter

The two types of ultrasonic flow meters are Doppler meters and Time-of-Travel (or Transit) meters.

1. Doppler meter

Doppler meters track frequency changes brought on by liquid flow. One side of the pipe has a case with two transducers mounted inside of it. Into the liquid being measured is sent a signal with a known frequency.

The pulse is reflected to the receiver element by solids, bubbles, or any other liquid discontinuity. The frequency of the returned pulse is shifted because the moving liquid that is causing the reflection is doing so. The frequency shift increases in direct proportion to the liquid’s speed.

2. Transit Meter

Transducers are mounted on either side of the pipe for transit meters. The devices are set up so that sound waves moving between them make a 45° angle with the direction of liquid flow. Depending on the transmission direction and the liquid’s velocity, the speed of the signal moving between the transducers increases or decreases.

By transmitting the signal alternately in both directions, it is possible to obtain a time-differential relationship proportional to the flow.

9. Mass Flow Meter

Mass flowmeters were created in response to the ongoing need for more precise flow measurements in mass-related processes (chemical reactions, heat transfer, etc.). There are many different designs, but the Coriolis mass flow meter is the one that is most frequently used for applications involving liquid flow. The Coriolis force, from which it derives its name, serves as the foundation for how it functions.

As opposed to volumetric flow, Coriolis flow meters are true mass meters that measure the mass rate of flow. The meter is linear without needing to be adjusted for changes in liquid properties because mass does not change.

When measuring liquids whose viscosity varies with the velocity at specific temperatures and pressures, the meter is particularly helpful. When compared to volumetric flow, Coriolis flow meters are true mass meters because they measure the flow’s mass rate directly. The meter is linear without needing to be adjusted for changes in liquid properties because mass does not change.

Additionally, it does away with the need to make adjustments for shifting pressure and temperature conditions. When measuring liquids whose viscosity varies with the velocity at specific temperatures and pressures, the meter is particularly helpful.